NEXT GENERATION SOLAR PANEL MODULE

BUILT FOR AUSTRALIAN CONDITIONS

SOLAR POWER MADE EASY

What Would You Like a Quote for?

NEXT GENERATION SOLAR MODULE

BUILT FOR AUSTRALIAN CONDITIONS

BUILT FOR AUSTRALIAN

CONDITIONS

HIGHEST

ENERGY

OUTPUT

SUPERIOR

LOW-LIGHT

PERFORMANCE

25 YEAR

INDUSTRY LEADING

WARRANTY

24/7 MONITORING

EVERY SINGLE

SOLAR PANEL

Solar panels have been around since 1883 and were invented by American inventor Charles Fritts, he made the first solar cells from selenium. Fast forward to 1954 where Bell Labs took a big leap in solar cell technology by creating the first type of silicon solar cells which are closer to the solar cells we use in solar panels today.

As the space race developed NASA then spent a lot of money on the research and development of solar cells and solar panels as they discovered they would be the best way to power various parts of the spacecraft whilst out in space.

From this development there was an emergence of new lower cost silicon cell technologies such as polycrystalline or multicrystalline solar cells and then higher efficiency solar cells and solar panels such as the mono crystalline solar cells and the HIT hybrid solar cell.

The most popular solar cells used in solar panels today are called PERC Solar cells, this stands for passivated emitter and rear contact. It basically means the cell features an additional layer on the back to allow more sunlight to be captured and turned into electricity. This makes the solar panel more efficient and lower cost per Watt to produce.

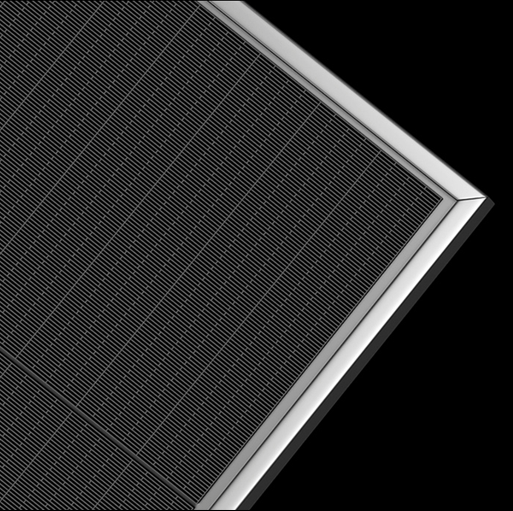

The Solar Cells featured in the REA Solar Panels are a modified version of this PERC solar cell technology. The PERC Cell is laser cut into smaller pieces then fused back together with a patented fusion technology to create a flexible solar sheet that provides more surface area to collect solar energy and lowers the amount of inactive space on the solar panel. That is one of the features that allow REA Solar to produce more power with less solar panels.

ADVANCED SOLAR PANEL TECHNOLOGY

Unleashing the true potential of the sun by utilising more solar energy with the technological breakthroughs in component raw materials and advanced manufacturing process. The Fusion Solar module fuses high efficiency crystalline cells intro a uniform sheet with a conductive rear contact paste increasing the solar surface area and durability of the solar module.

HIGHER EFFICIENCY

MORE RELIABLE

SIMPLY SMARTER

Featuring a uniform cell construction the Fusion module increases the solar radiation conversion by maximizing available cell space. The Fusion module utilizes rear contact connection through a flexible conductive paste eliminating conventional soldered copper ribbons giving the module superior performance, reliability and a beautiful sleek appearance.

POWER UP TO

465 w

Peak

High Density Cell

Inactive Space

Reduction

50%

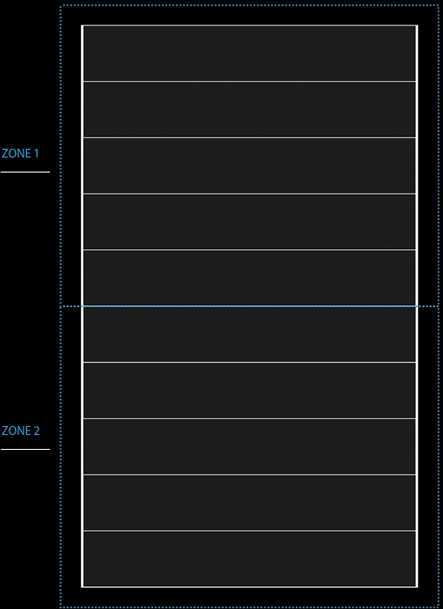

Electricity designed to reduce solar power losses caused by shadowing across the module by utilizing parallel connections between each module zone. This feature also increases reliability as the module has no cell to cell soldered connections.

BREAKTHROUGH CELL DESIGN

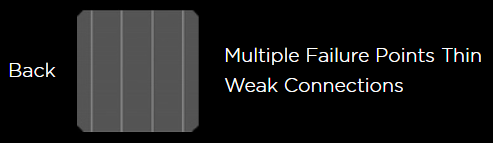

Conventional

Flexible Fusion Cell

Connection

Developing a new unique cell structure by fusing high efficiency cell sections into a Fusion solar sheet enabling more solar performance from a smaller space. The design also reduces cell operating temperatures by dissipating heat over a larger surface area and increases the cell flexibility and strength by removing the requirement for soldered cell to cell connections.

Most Common

Cell Failure Causes

Engineered

to Last

Reliable Construction

Conventional Solar Panels tend to lose power over time due to the corrosion and breakage of its cell interconnection points. The Fusion cell design eliminates 82% of the design flaws in conventional solar panel thus increasing its lifetime performance and reliability

AC MODULE DESIGN

SMARTER

SAFER

22v

the operating

window.

startup can be as

high as 150v.

SPECIFICATIONS

REA Power - REA Fusion 430 ACM

TECHNOLOGY COMPARISON

Enphase Energized

No mounting a string inverter

Design changes in field are difficult

Design changes in field are difficult

produced up to 3.1% more energy

system failure

system failure